Mechanical Behavior Performance of Gaskets

Load-Deformation Behavior

Today, we continue to introduce the mechanical behavior properties of gaskets - load-deformation behavior.

Characteristics of Hysteresis Curve

Gaskets are different from ideal elastic materials; usually, they are not completely elastic, and this feature is very prominent in their load-deformation behavior.

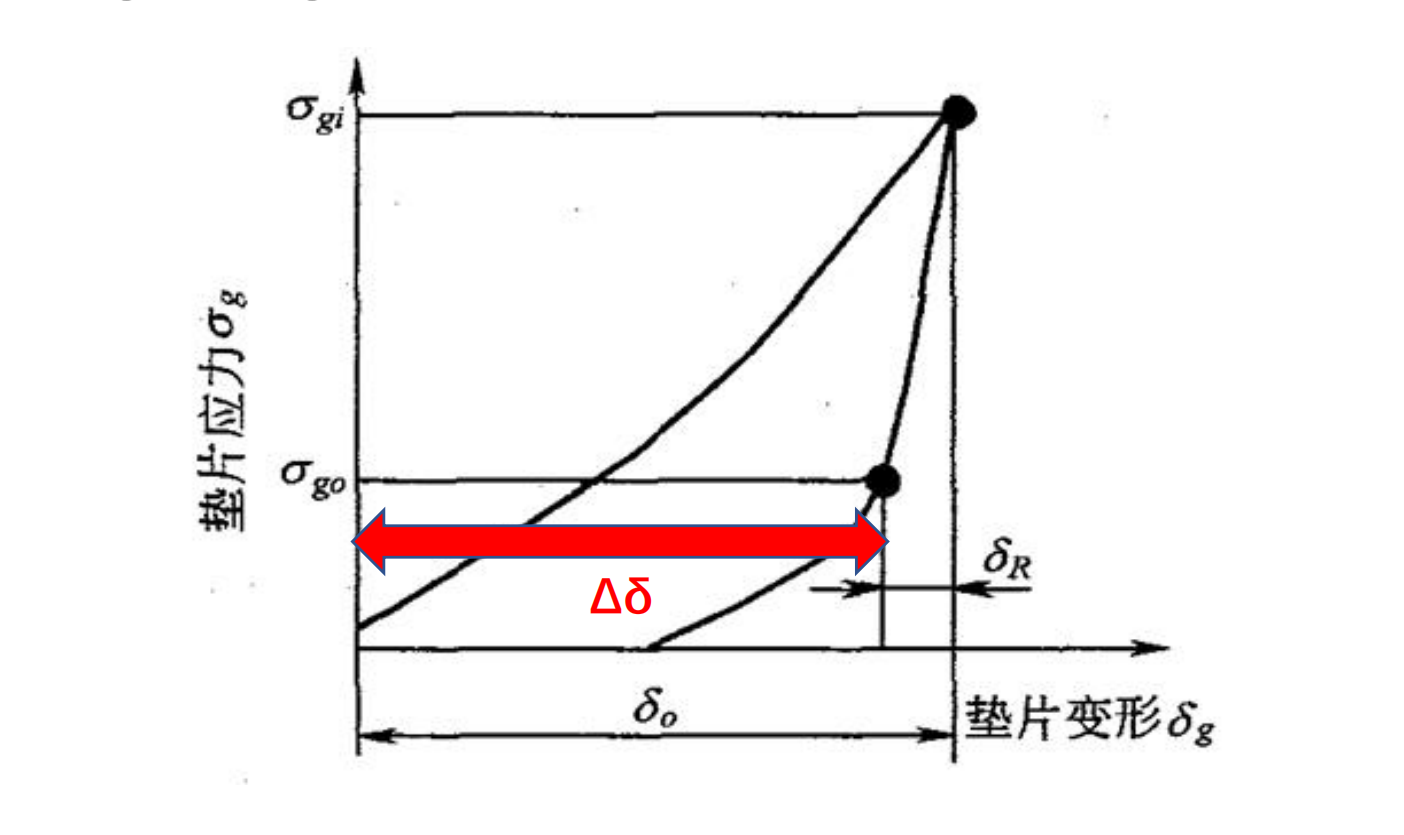

Picture: Characteristics of Hysteresis Curve

First of all, there is no single elastic response relationship between σg and δg, and the curve shows nonlinear characteristics. More importantly, its stress-deformation curve will show the characteristics of a hysteresis curve (as shown in the above figure), which indicates the existence of residual deformation.

BMC Nuclear Power Plant Seals Resist Alternating Loads

For example, in the working state, Δδ = δo - δR is the residual deformation of the gasket, which is the difference obtained by subtracting the rebound amount δR after the stress drops from the initial compression amount δo.

It is worth noting that the residual deformation of some gaskets may gradually disappear over time, which makes their compression characteristics different under assembly load (during installation) and operating load (during work).

It is crucial to understand this: the compression state during assembly may not fully represent the working state. In design, the influence of residual deformation must be fully considered to ensure the reliability of long-term sealing.

BMCSWG: Excellent Rebound Performance and Sealing Performance

Ingenious Seal Mastery

For sealing leakage issues, Baohua provides solutions. If you have any doubts about sealing technology, please pay attention to Suzhou Baohua and feel free to consult, comment, or leave a message! Thank you all! We will continue to talk about load-deformation behavior in the next issue. See you next time!

Email:[email protected]

Email:[email protected]