Mechanical Behavior Performance of Gaskets

Load-Deformation Behavior

Today, we continue to introduce the mechanical behavior properties of gaskets - load-deformation behavior.

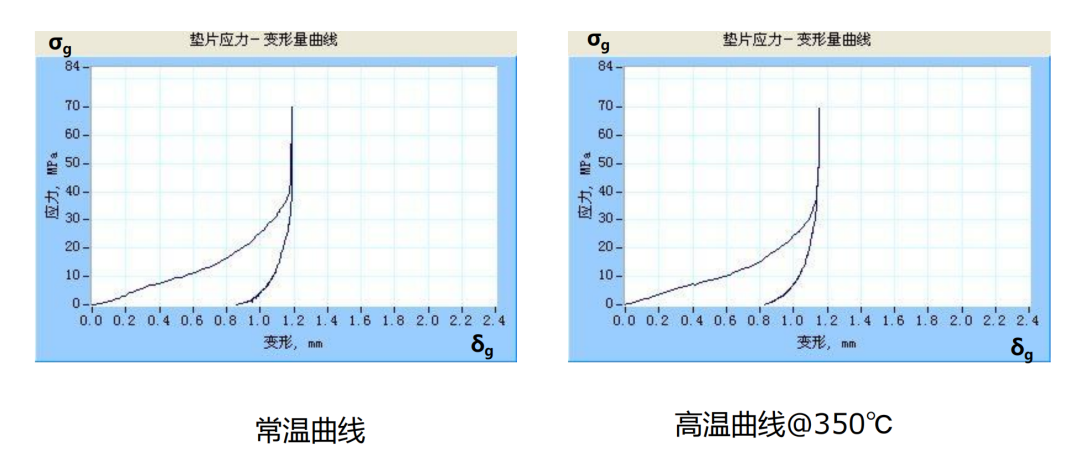

Relationship Between σg and δg Affected by Temperature

Temperature is a crucial factor influencing the mechanical properties of gaskets. The relationship between σg (gasket stress) and δg (gasket deformation) of gaskets changes significantly under different temperatures.

As shown in the comparison between the curves at room temperature and high temperature (350℃) in the figure above, temperature has two main influencing trends on the load-deformation curve:

On one hand, high temperature causes thermal expansion of the material.

On the other hand, the elastic modulus of the material decreases.These two factors work together, making the gasket "softer" at high temperatures.

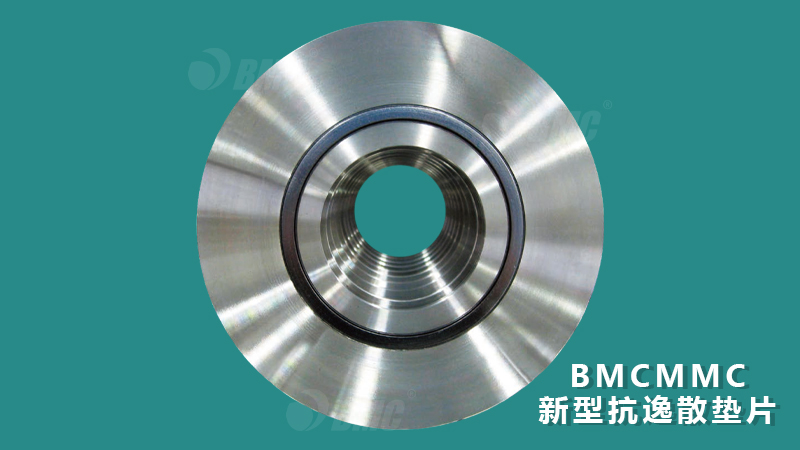

BMCMMC: High-Temperature and High-Pressure Resistant High-Performance Sealing Gasket for Petrochemical Industry

The specific manifestations are as follows: under the same stress, the compression amount of the gasket at high temperature is lower than that at room temperature; at the same time, the gasket stress also decreases slightly.

BMCSG: For high temperature resistant pipeline equipment flanges

This means that under high-temperature working conditions, the load-bearing capacity and resilience of the gasket may be weakened. Therefore, the impact of temperature must be considered in sealing design, and a gasket type that can maintain stable load-deformation characteristics at the target temperature should be selected.

Ingenious Seal Mastery

For sealing leakage issues, Baohua provides solutions. If you have any doubts about sealing technology, please pay attention to Suzhou Baohua and feel free to consult, comment, or leave a message! Thank you all!See you in the next issue!

Email:[email protected]

Email:[email protected]